By John S. Retsios

One of the most common questions I am asked to answer as a technician and trainer in the use of hydraulic rescue tools is whether there is compatibility of couplings between different companies. This is a very interesting question which I wish to answer analytically through this article.

Every company of hydraulic rescue tools adjusts the construction and the innovations of its tools according to the highest sale share that it has worldwide. European companies usually aim at Europe but in other countries, too. The construction of their tools is under European legislations and specifications, sometimes making further adjustments in certain countries, such as in the USA, so that there can be adjusted to the USA principles, too.

Compatibility has to do with the so called quick couplings and the single quick coupling of hydraulic tools whether they are pumps or spreaders, etc. A main factor of compatibility is the high pressure hose that connects tools and pumps. But first, some specifications need to be made about the high pressure hoses of hydraulic tools.

These hoses are made of a mixture of plastic and vinyl, with the addition of Kevlar fibres and they aim at being durable and resistant when receiving high pressures >650 bar and external strain. They are found in different colours, combinations and length as well as in different sizes and types of screw threads in the edge couplings.

Many friends ask me what their duration is. Every high pressure hose for hydraulic tools lasts between seven to ten years, according to the manufacturer.

The purpose of the expiration date is to be made sure that there won’t EVER be rupture of the hose, with unexpected results and emission of hot oil under pressure. A way to check is to look at the end of the hose exactly where the manufacturing date has been engraved. You can also find the date printed on top (it refers to which three-month period it was manufactured). From this date on, you can calculate 10 years maximum. If the hose exceeds 10 years, I unreservedly recommend that you change to a new one for safety reasons.

In the case of a high pressure hose not having expired yet but with visible signs of external eruption, it needs again to be replaced.

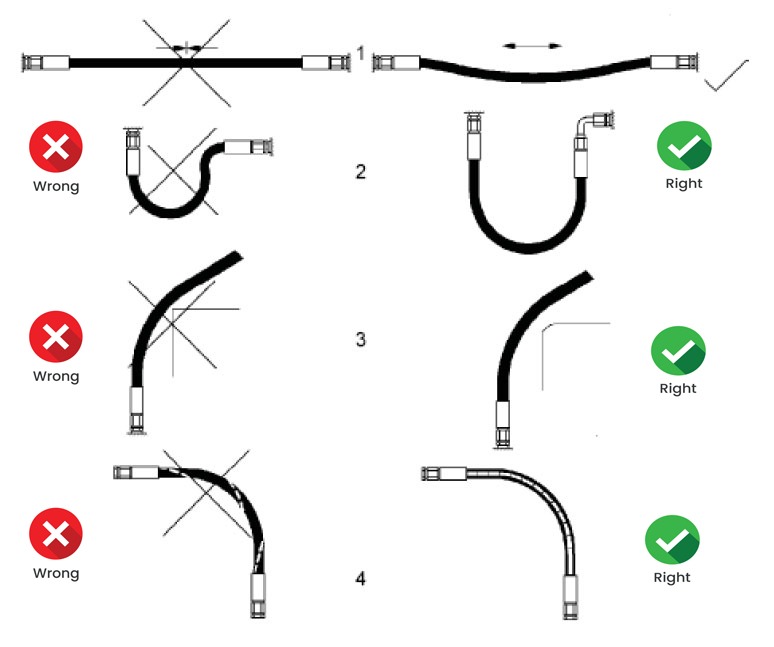

Attention should be paid when connecting the couplings so that no DIRT goes inside because then the hose runs the risk of “choking up”, leaving no other option but to be needing replacement. In addition, “high pressure hoses should be dealt with care” because bendings, wrong angles and wrong extensions will wear them out and ruin them. What follows is examples of right and wrong.

As far as their maintenance is concerned, what has to be stressed is that they often have to be externally cleaned so that we can notice possible damage which we might have time to prevent from it becoming more serious if it is visible. As cleaning material, what we suggest is mild solutions with common dishwashing detergents or with the suggested way of using degreaser having Vinyl safe, O’Ring safe indications.

Cleaning of the inside of couplings should be cleaned with same quality oil that we use for the hydraulic pump and then with pressured air on the inside of the coupling for a while. After having dried, apply lithium grease.

In relation to the couplings, I would like to say that if they don’t buckle up (with one another), DON’T put pressure or try to unbuckle them because that will result to their damage. Check first if there is trapped pressure, if something is damaged or buckled up in the wrong way. If you don’t understand what the problem is refer to a specialist because their repair can be costly if you damage anything without realizing it.

How many couplings are there and what are their similarities?

In this article, we will mention the 10 most known companies which construct hydraulic tools and the possibilities of compatibility among them.

In alphabetical order, the construction companies are (press to watch their websites) :

- AMKUS Rescue Systems

- Champion Rescue Tools

- Genesis Rescue Systems

- Holmatro Rescue Systems

- HURST Rescue

- Lancier Hydraulik Systems

- LUKAS Hydraulik GmbH

- RESQTEC Systems

- TNT Rescue Systems

- WEBER Rescue Systems

With the exception of 6 companies who share the same coupling, all the other companies have huge differences among them making the tools credible, according to the manufacturer but not fully compatible.

AMKUS Rescue Systems

Country : USA, Wisconsin

Type of coupling: Mono Coupling

Compatibility with : Lancier and Genesis, Weber, Lucas (under discussion and evaluation)

Clasp of 180 degree rotation

Advantages (+) : Credible coupling with compatibility with Lancier & possible compatibility with Genesis, Weber, Lucas (this is under research because it works under 720 bar whereas the companies mentioned before work at 700 bar), ability of 360 degree rotation of the coupling which helps in the development of the hydraulic hose.

Disadvantages (-) : The taps are made of plastic which, after use and while time passes, don’t apply correctly so the get loose and come out. Good cleaning is needed if dirt falls inside.

Champion Rescue Tools

Country : USA, California

Type of coupling: Standard Coupling

Compatibility: NO

Clasp with rotation and pulling of external dactyl

Advantages (+) : Strong construction, decreased damages

Disadvantages (-) : Difficulty in connection, possibility of trapped oil in the coupling, no compatibility with other construction companies & it can’t rotate 360 degrees to ease the unrolling of the hose.

Genesis Rescue Systems

Country : USA, Glenview

Type of coupling: OSC Coupling

Compatibility with : Weber, Lucas

Clasp of 180 degree rotation

Advantages (+) : Credible coupling with compatibility with other two construction companies, ability of 360 degree rotation of the coupling which helps in the development of the hydraulic hose. Connection and disconnection of under pressure hydraulic oils without needing to close the hydraulic pump.

Disadvantages (-) : The taps are made of plastic which, after use and while time passes, don’t apply correctly so the get loose and come out. Good cleaning is needed if dirt falls inside.

Holmatro Rescue Systems

Country : the Netherlands

Type of coupling: Core Coupling System

Compatibility : NO

Clasp with thrust

Advantages (+) : Credible coupling with ability of 360 degree rotation of the coupling which helps in the development of the hydraulic hose. Connection and disconnection of under pressure hydraulic oils without needing to close the hydraulic pump. Ability of connection with one hand only through thrust. Single connection hose through the core system which decreases its total weight.

Disadvantages (-) : No compatibility with other construction companies of hydraulic tools.

Sometimes you need a pressure relief plug if pressure build up inside the hose.

HURST Rescue

Country : USA, Shelby

Type of coupling: Stream Line System

Compatibility: NO

Advantages (+) : Credible coupling with ability of 360 degree rotation of the coupling which helps in the development of the hydraulic hose. Connection and disconnection of under pressure hydraulic oils without needing to close the hydraulic pump according to the manufacturer.

Disadvantages (-) : The taps are made of plastic which, after use and while time passes, don’t apply correctly so the get loose and come out. Good cleaning is needed if dirt falls inside.

Lancier Rescue Systems

Country : Germany, member AWG

Type of coupling: Single Coupling System

Compatibility with : Amkus and Genesis, Weber, Lucas (under discussion and evaluation)

Clasp of 180 degree rotation.

Advantages (+) : Credible coupling with compatibility with Amkus & possible compatibility with three other companies this is under research because it works under 720 bar whereas the companies mentioned before work at 700 bar), ability of 360 degree rotation of the coupling which helps in the development of the hydraulic hose.

Disadvantages (-) : The taps are made of plastic which, after use and while time passes, don’t apply correctly so the get loose and come out. Good cleaning is needed if dirt falls inside.

Lucas Rescue Systems

Country : Germany

Type of coupling: Stream Coupling System

Compatibility with : Genesis, Weber

Clasp of 180 degree rotation

Advantages (+) : Credible coupling with compatibility with other two construction companies, ability of 360 degree rotation of the coupling which helps in the development of the hydraulic hose. Connection and disconnection of under pressure hydraulic oils without needing to close the hydraulic pump.

Disadvantages (-) : The taps are made of plastic which, after use and while time passes, don’t apply correctly so the get loose and come out. Good cleaning is needed if dirt falls inside

Resqtec Rescue Systems

Country : the Netherlands

Type of coupling: GrootBeeld System

Compatibility: NO

Advantages (+) : Very easy connection through a patented coupling with good quality plastic clasp.

Disadvantages (-) : Weakness of 360 degree rotation of the coupling, no compatibility with other companies. It can’t adjust a single-hose system.

TNT Rescue Systems

Country : USA

Type of coupling: Nexus Coupler & Flat face coupler

Compatibility: NO

Clasp with thrust or with 180 degree rotation

Advantages (+) : Strong construction, decrease of damages, patented coupling of Nexus coupler type that resembles the construction of Single Coupling used by at least 4 construction companies. . Ability of connection and disconnection of under pressure hydraulic oils without needing to close the hydraulic pump according to the manufacturer.

Disadvantages (-) : Possibility of oil entrapment in the coupling, no compatibility with other construction companies. The coupling can’t rotate 360 degrees for the easy unrolling of the the hose. It can’t adjust single high pressure hose of Coax or Core type.

WEBER Rescue Systems

Country : Austria

Type of coupling: Single Coupling System

Compatibility with : Genesis, Lucas

Clasp of 180 degree rotation

Advantages (+) : Credible coupling with compatibility of two other construction companies ability of 360 degree rotation of the coupling which helps in the development of the hydraulic hose. . Ability of connection and disconnection of under pressure hydraulic oils without needing to close the hydraulic pump. It can also adjust single high pressure hose of type Coax.

Disadvantages (-) : The taps are made of plastic which, after use and while time passes, don’t apply correctly so the get loose and come out. Good cleaning is needed if dirt falls inside.

All in all, we see that 90 % of the construction companies tend to use the system of single connection of couplings and they reject the use of old couplings (two separate ones) and, of course, they promote the use of single high pressure hose like we saw in Holmatro or in Weber.

I have to stress that a factor that can lead us to the use and purchase of a hydraulic rescue series is obviously the compatibility and according to what I have described you can see yourselves that the companies Weber, Genesis, Lucas, Lancier, Hurst & Amkus use the same coupling with different names. This is extremely interesting since we can see that 6 out of 10 try to place the technical specifications of their couplings in the same frame. This is something that will not only offer the ability of parallel connection of tools with different brands but also the ease of practical use in trainings and in actual incidents. (Be aware of the different oil pressures among 350 bar, 700 bar, 720 bar as well as of the content in litres of high pressure oil because they can’t make rescue tools operate in a correct way even if they have the same coupling according to specifications).

In my opinion, it is a big mistake if, for example, there is a professional fire service or substation with a specific rescue hydraulic series and a volunteer team or substation with another rescue hydraulic series with no compatibility between them. In a case of a car accident or in case of an earthquake in which they will both have to respond, how will they cooperate if there is lack of compatible material or if there is simultaneous use of tools so that they an avoid possible strain due to the continuous use? Therefore, I suggest, if of course there is the right mood and willingness, that meetings of these services involved take place before the purchase of rescue hydraulic tools and I suggest that the topic of the meeting discussion be the compatibility, the credibility, the maintenance and finally the cost of the purchase.

I hope that I have answered the initial question of fellow colleagues and that I have possibly offered my piece of knowledge for all of you in the world of knowledge of technical rescue.

John S. Retsios